- DELTA PRODUCTS

- - Delta Products1

- - Delta Products2

- - Delta Products3

- - Delta Products4

- - Delta Products5

- OMRON PRODUCT

- - Omron Products

- ELECTRIC DRIVE

- - Low Voltage Inverter

- - High Voltage Inverter

- - Intelligent Integral Machine

- INDUSTRIAL CONTROL

- - Servo System

- - PLC

- - HMI

- A/C Drives

- - Architecture Drives

- - Compact Drives

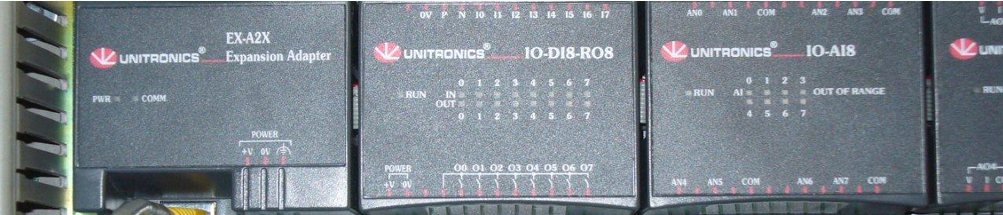

- Programmable Controllers

- - Large Control Systems

- - Micro & Nano Control Systems

- - Small Control Systems

- HMI Human Machine Interface

- - Computers, Extreme Environment

- - Computers, Industrial Environment

- - Graphic Terminals

- - Industrial Monitors

Home »

Our Products » Delta Products

Delta Products

Delta Elevator Door BLDCM Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta Elevator

Door BLDCM Motors & Drives

FEATURES

Brushless DC Motors and Drives (BLDCM) is a kind of 3-phase induction synchronous motor of permanent magnets with brushless structure. It is compact size and light weight. By adopting electronic commutator, it makes lower mechanical/electrical noise and no high temperature and dust caused by friction. In addition, it won’t produce rotor loss due to low inertia of rotor and high-speed operation. Therefore, it saves energy during heavy-load operation and is higher performance than traditional motor. For the BLDC with new technology, it has high-torque output at low speed and self-protection for over-heat, over-current, phase loss and leakage current.

SPECIFICATIONS

Power range:250W

Speed range:600rpm

Square-wave PWM control mode, feedback signal of Hall sensor Low temperature rise, high efficiency and energy saving Compact size, space saving and easy installation Easy maintenance, low noise and electromagnetic interference Constant output torque for easy control Its high efficiency is greater than the induction motor

Brushless DC Motors and Drives (BLDCM) is a kind of 3-phase induction synchronous motor of permanent magnets with brushless structure. It is compact size and light weight. By adopting electronic commutator, it makes lower mechanical/electrical noise and no high temperature and dust caused by friction. In addition, it won’t produce rotor loss due to low inertia of rotor and high-speed operation. Therefore, it saves energy during heavy-load operation and is higher performance than traditional motor. For the BLDC with new technology, it has high-torque output at low speed and self-protection for over-heat, over-current, phase loss and leakage current.

SPECIFICATIONS

Power range:250W

Speed range:600rpm

Square-wave PWM control mode, feedback signal of Hall sensor Low temperature rise, high efficiency and energy saving Compact size, space saving and easy installation Easy maintenance, low noise and electromagnetic interference Constant output torque for easy control Its high efficiency is greater than the induction motor

APPLICATIONS

Elevator door, carriage door and automatic door

Elevator door, carriage door and automatic door

Delta Brushless Integrated BLDCM Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta

Brushless High Performance and Integrated BLDCM Motors and Drives

FEATURES

Brushless DC Motors and Drives (BLDCM) is a kind of 3-phase induction synchronous motor of permanent magnets with brushless structure. It is compact size and light weight. By adopting electronic commutator, it makes lower mechanical/electrical noise and no high temperature and dust caused by friction. In addition, it won’t produce rotor loss due to low inertia of rotor and high-speed operation. Therefore, it saves energy during heavy-load operation and is higher performance than traditional motor. For the BLDC with new technology, it has high-torque output at low speed and self-protection for over-heat, over-current, phase loss and leakage current.

Brushless DC Motors and Drives (BLDCM) is a kind of 3-phase induction synchronous motor of permanent magnets with brushless structure. It is compact size and light weight. By adopting electronic commutator, it makes lower mechanical/electrical noise and no high temperature and dust caused by friction. In addition, it won’t produce rotor loss due to low inertia of rotor and high-speed operation. Therefore, it saves energy during heavy-load operation and is higher performance than traditional motor. For the BLDC with new technology, it has high-torque output at low speed and self-protection for over-heat, over-current, phase loss and leakage current.

SPECIFICATIONS

Power range:250-750W

Speed range:150-1750rpm

Square-wave PWM control mode, feedback signal of Hall sensor Easy maintenance, low noise and electromagnetic interference Constant output torque for easy control Its high efficiency is greater than the induction motor Integrated driver with digital I/O and RS-485 communication Over-current/over-voltage/over-load protections

Power range:250-750W

Speed range:150-1750rpm

Square-wave PWM control mode, feedback signal of Hall sensor Easy maintenance, low noise and electromagnetic interference Constant output torque for easy control Its high efficiency is greater than the induction motor Integrated driver with digital I/O and RS-485 communication Over-current/over-voltage/over-load protections

APPLICATIONS

HVAC, washing machine and clothes dryer.

HVAC, washing machine and clothes dryer.

Delta AFE2000 Active Front End Unit

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta AFE2000

Active Front End Unit

FEATURES

Incorporating years of experience in AC motor drive development, Delta introduces the innovative AFE2000. This unit is designed for a wide range of applications and it achieves outstanding energy saving results. The AFE2000 does not dissipate excess heat into the air but converts it into reusable power that can be supplied back to the mains. The AFE2000 is yet another Delta product that contributes to improving efficiency and productivity and that fulfills our mission “to provide innovative, clean and efficient energy solutions for a better tomorrow”.

Incorporating years of experience in AC motor drive development, Delta introduces the innovative AFE2000. This unit is designed for a wide range of applications and it achieves outstanding energy saving results. The AFE2000 does not dissipate excess heat into the air but converts it into reusable power that can be supplied back to the mains. The AFE2000 is yet another Delta product that contributes to improving efficiency and productivity and that fulfills our mission “to provide innovative, clean and efficient energy solutions for a better tomorrow”.

Delta ASDA-A AC Servo Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta AC Servo

Motor and Drive ASDA-A Series

FEATURES

The A series is an omnibearing integrated servo system with advanced functions. Not only pulse commands and analog voltage signal control, the A series also provides internal point-to-point position control mode (8 internal programmable registers) and offers various internal control functions such as: indexing, feed step control function, internal auto-running control mode, and move to Home function, etc. for a vast range of applications. In addition, the A series implements Modbus communication protocol as a standard, to perfectly meet the requirements of motion control applications for multiple points. The A series servo system provides a better solution for industrial processing machinery and motion control equipment.

The A series is an omnibearing integrated servo system with advanced functions. Not only pulse commands and analog voltage signal control, the A series also provides internal point-to-point position control mode (8 internal programmable registers) and offers various internal control functions such as: indexing, feed step control function, internal auto-running control mode, and move to Home function, etc. for a vast range of applications. In addition, the A series implements Modbus communication protocol as a standard, to perfectly meet the requirements of motion control applications for multiple points. The A series servo system provides a better solution for industrial processing machinery and motion control equipment.

SPECIFICATIONS

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; from 2kW to 3kW, 3-phase

Input power supply: AC 200V ~ 230V

Built-in Position / Speed / Torque control modes

8 internal programmable registers (point-to-point position control)

Internal control function: Indexing, Feed step control function (for cutting applications)

Internal control function: Internal auto-running control mode

Internal control function: Move to Home (Homing) function

Internal control function: Position teaching function (JOG mode)

Programming is done via the built-in keypad or using Delta’s free Windows® based software where the user can store, teach, and monitor the operation of the servo system. Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; from 2kW to 3kW, 3-phase

Input power supply: AC 200V ~ 230V

Built-in Position / Speed / Torque control modes

8 internal programmable registers (point-to-point position control)

Internal control function: Indexing, Feed step control function (for cutting applications)

Internal control function: Internal auto-running control mode

Internal control function: Move to Home (Homing) function

Internal control function: Position teaching function (JOG mode)

Programming is done via the built-in keypad or using Delta’s free Windows® based software where the user can store, teach, and monitor the operation of the servo system. Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422

APPLICATIONS

Cutting control of machining center, rotary indexing machine, sealing machine, shearing machine, feeding machine, carving machine, lathe, high-speed winding machine, testing / inspecting Machine, cutting machine, SMT machine, molding machine

Cutting control of machining center, rotary indexing machine, sealing machine, shearing machine, feeding machine, carving machine, lathe, high-speed winding machine, testing / inspecting Machine, cutting machine, SMT machine, molding machine

Delta ASDA-A AC Servo Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta AC Servo

Motor and Drive ASDA-A+ Series

FEATURES

The A+ series is a new type of omnibearing integrated servo system with advanced functions. It is able to combine with medium / high servo motors from 3kW to 7.5kW ( torque output from 19.1 N-M to 47.74 N-M) and is equipped with incremental 20-bit (1280000 ppr) optical encoder, providing more accurate positioning control for high-precision processing industries or the machine applications where high responsiveness and stiffness is needed to reject high torque disturbances. With A and AB series, Delta provide a complete servo product line (from 100W to 7.5kW) to fully support our customers’ needs and offer various options for high torque applications.

The A+ series is a new type of omnibearing integrated servo system with advanced functions. It is able to combine with medium / high servo motors from 3kW to 7.5kW ( torque output from 19.1 N-M to 47.74 N-M) and is equipped with incremental 20-bit (1280000 ppr) optical encoder, providing more accurate positioning control for high-precision processing industries or the machine applications where high responsiveness and stiffness is needed to reject high torque disturbances. With A and AB series, Delta provide a complete servo product line (from 100W to 7.5kW) to fully support our customers’ needs and offer various options for high torque applications.

SPECIFICATIONS

A wide power range: from 4.5kW to 7.5kW, 3-phase

Input power supply: AC 200V ~ 230V

Frequency characteristics (Responsiveness): 550Hz

Incremental 20-bit (1280000 ppr) optical encoder

Medium / High inertia servo motors are available including: 3kW, 3.5kW, 4.5kW, 5.5kW, 7.5kW.

Max. input frequency: Line receiver 4Mbps for high-speed motion command.

Built-in Position / Speed / Torque control modes

8 internal programmable registers (point-to-point position control)

Various internal control functions for a vast range of applications (as A and AB series) Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422

A wide power range: from 4.5kW to 7.5kW, 3-phase

Input power supply: AC 200V ~ 230V

Frequency characteristics (Responsiveness): 550Hz

Incremental 20-bit (1280000 ppr) optical encoder

Medium / High inertia servo motors are available including: 3kW, 3.5kW, 4.5kW, 5.5kW, 7.5kW.

Max. input frequency: Line receiver 4Mbps for high-speed motion command.

Built-in Position / Speed / Torque control modes

8 internal programmable registers (point-to-point position control)

Various internal control functions for a vast range of applications (as A and AB series) Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422

APPLICATIONS

Spring machine, bending machine, bending press, feeding machines, electric injection molding machine, double column type machining center, presses machine

Spring machine, bending machine, bending press, feeding machines, electric injection molding machine, double column type machining center, presses machine

Delta ASDA-AB AC Servo Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta AC Servo

Motor and Drive ASDA-AB Series

FEATURES

The AB series is a high performance digital servo system with advanced functions and supports various motor options including low, medium and high inertia servo motors to meet different application needs. It offers many motion control functionalities for a wide range of industry and machine applications, as well as provided in the A series. In addition, the AB series implements Modbus communication protocol as a standard, to connect with Delta’s programmable logic controller (PLC) and human machine interface (HMI), and establish the advanced architecture of the communication control system. Major applications include a vast range of machine tools and processing machines for various industries.

The AB series is a high performance digital servo system with advanced functions and supports various motor options including low, medium and high inertia servo motors to meet different application needs. It offers many motion control functionalities for a wide range of industry and machine applications, as well as provided in the A series. In addition, the AB series implements Modbus communication protocol as a standard, to connect with Delta’s programmable logic controller (PLC) and human machine interface (HMI), and establish the advanced architecture of the communication control system. Major applications include a vast range of machine tools and processing machines for various industries.

SPECIFICATIONS

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; from 2kW to 3kW, 3-phase Input power supply: from 100W to 400W, AC 100V ~ 115V; from 100W to 3kW, AC 200V ~ 230V Frequency characteristics (Responsiveness): 450Hz Incremental 2500ppr optical encoder Built-in Position / Speed / Torque control modes 8 internal programmable registers (point-to-point position control) Various internal control functions for a vast range of applications (as A series) Different inertia motors, from 1000 r/min to 3000 r/min are connectable. Brake, oil seal, etc. motor options are available for different kinds of application fileds. Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422.

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; from 2kW to 3kW, 3-phase Input power supply: from 100W to 400W, AC 100V ~ 115V; from 100W to 3kW, AC 200V ~ 230V Frequency characteristics (Responsiveness): 450Hz Incremental 2500ppr optical encoder Built-in Position / Speed / Torque control modes 8 internal programmable registers (point-to-point position control) Various internal control functions for a vast range of applications (as A series) Different inertia motors, from 1000 r/min to 3000 r/min are connectable. Brake, oil seal, etc. motor options are available for different kinds of application fileds. Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422.

APPLICATIONS

Cutter/Turret control of machine tool, X-Y table control, sealing machine, feeding machine, carving machine, lathe, high-speed winding machine, cutting applications, textile equipment.

Cutter/Turret control of machine tool, X-Y table control, sealing machine, feeding machine, carving machine, lathe, high-speed winding machine, cutting applications, textile equipment.

Delta ASDA-B AC Servo Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta AC Servo

Motor and Drive ASDA-B Series

FEATURES

The B series is a digital servo system with standard functions. It provides built-in Position / Speed / Torque control modes and supports pulse command input and analog signal control. Parameters editing and operation is done via an optional handheld digital keypad. The gain tuning function allows easy operation and the internal memory blocks shorten the parameters upload and download time. The B series is a cost-effective and satisfactory servo system that fills the most basic and functional requirements of industrial automation field.

The B series is a digital servo system with standard functions. It provides built-in Position / Speed / Torque control modes and supports pulse command input and analog signal control. Parameters editing and operation is done via an optional handheld digital keypad. The gain tuning function allows easy operation and the internal memory blocks shorten the parameters upload and download time. The B series is a cost-effective and satisfactory servo system that fills the most basic and functional requirements of industrial automation field.

SPECIFICATIONS

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; 2kW, 3-phase Input power supply: AC 200V ~ 230V Available motor capacity: from 100W to 2kW Built-in Position / Speed / Torque control modes Pulse commands and analog voltage signals are accessed via input / output interface – CN1. D-sub connector is provided for no troublesome wiring and connection. Convenient handheld digital keypad is helpful for parameters editing and operation. Internal memory blocks stored in the handheld digital keypad allows the users to read and write the parameters of the servo drive. Easy gain tuning is done via the handheld digital keypad or using Delta’s free Windows® based software where the user can store, teach, and monitor the operation of the servo system. Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; 2kW, 3-phase Input power supply: AC 200V ~ 230V Available motor capacity: from 100W to 2kW Built-in Position / Speed / Torque control modes Pulse commands and analog voltage signals are accessed via input / output interface – CN1. D-sub connector is provided for no troublesome wiring and connection. Convenient handheld digital keypad is helpful for parameters editing and operation. Internal memory blocks stored in the handheld digital keypad allows the users to read and write the parameters of the servo drive. Easy gain tuning is done via the handheld digital keypad or using Delta’s free Windows® based software where the user can store, teach, and monitor the operation of the servo system. Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485

APPLICATIONS

Filling and bottling equipment, feeding machine, electro-discharge machine, lathe, printing equipment, crochet machine, carving machine

Filling and bottling equipment, feeding machine, electro-discharge machine, lathe, printing equipment, crochet machine, carving machine

Delta ASDA-B2 AC Servo Motors

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta AC Servo

Motor and Drive ASDA-B2 Series

INTRODUCTION

The power rating of the ASDA-B2 series is offered from 0.1kW to 3kW. The superior properties of this series emphasize on “built-in generic functions for general-purpose applications” and “avoiding variable costs from mechatronics integration.” When Delta’s ASDA-B2 series is in use, the users can conveniently complete assembly, wiring and operation setups. In addition, in switching from other brands to Delta’s ASDA-B2 series, outstanding quality and features, and complete product lineup make the replacement easy and quick to achieve. Using Delta ASDA-B2 series, not only the wiring and operation becomes much easier, and the requirements of general-purpose machine tools for the market could be satisfied as well. Moreover, the customized solutions are available on request for different industries so that make ASDA-B2 series be widely popular and always in demand by the customers in the field of industrial automation.

The power rating of the ASDA-B2 series is offered from 0.1kW to 3kW. The superior properties of this series emphasize on “built-in generic functions for general-purpose applications” and “avoiding variable costs from mechatronics integration.” When Delta’s ASDA-B2 series is in use, the users can conveniently complete assembly, wiring and operation setups. In addition, in switching from other brands to Delta’s ASDA-B2 series, outstanding quality and features, and complete product lineup make the replacement easy and quick to achieve. Using Delta ASDA-B2 series, not only the wiring and operation becomes much easier, and the requirements of general-purpose machine tools for the market could be satisfied as well. Moreover, the customized solutions are available on request for different industries so that make ASDA-B2 series be widely popular and always in demand by the customers in the field of industrial automation.

FEATURES

High-resolution encoder with 17-bit (160,000 p/rev) is equipped as a standard feature which satisfies the application needs of high precision positioning control and stable rotation at low speed. Satisfy High Precision Positioning Requirements Support pulse input (up to 4Mbps) and analog voltage two kinds of command. Built-in position, speed and torque three control modes (speed and torque mode could be controlled via internal parameters or analog voltage command). There auto notch filters are provided to suppress the mechanical resonance automatically and make the system operate more smoothly. Offer Easy-To-Install Solution for Simple Start-Up Motor sizing software is offered for the customers to conduct the estimation of the equipment conveniently. ASDA-Soft configuration software (tuning software) is provided for the customers to meet the performance requirements quickly. Easy-to-use digital keypad is ideal for setting parameters and monitoring the servo drive and motor directly. Servo motor provides brake, oil seal etc. optional configurations for the requirements of different applications. Reduce Maintenance and Wiring Cost for Versatile Operation Existing power cables and encoder cables for ASDA series could be used still. When upgrading, there is no need to purchase new accessories. The control circuit and main power circuit is separated, safety is increased and maintenance is much easier. 400W and above servo drive is built-in with regenerative resistor, significantly save the wiring and cost. Two analog input terminals (CN5) are provided, easily monitor and the status of the servo motor.

High-resolution encoder with 17-bit (160,000 p/rev) is equipped as a standard feature which satisfies the application needs of high precision positioning control and stable rotation at low speed. Satisfy High Precision Positioning Requirements Support pulse input (up to 4Mbps) and analog voltage two kinds of command. Built-in position, speed and torque three control modes (speed and torque mode could be controlled via internal parameters or analog voltage command). There auto notch filters are provided to suppress the mechanical resonance automatically and make the system operate more smoothly. Offer Easy-To-Install Solution for Simple Start-Up Motor sizing software is offered for the customers to conduct the estimation of the equipment conveniently. ASDA-Soft configuration software (tuning software) is provided for the customers to meet the performance requirements quickly. Easy-to-use digital keypad is ideal for setting parameters and monitoring the servo drive and motor directly. Servo motor provides brake, oil seal etc. optional configurations for the requirements of different applications. Reduce Maintenance and Wiring Cost for Versatile Operation Existing power cables and encoder cables for ASDA series could be used still. When upgrading, there is no need to purchase new accessories. The control circuit and main power circuit is separated, safety is increased and maintenance is much easier. 400W and above servo drive is built-in with regenerative resistor, significantly save the wiring and cost. Two analog input terminals (CN5) are provided, easily monitor and the status of the servo motor.

Delta ROE-A Series Rotary Optical Encoders

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta Rotary

Optical Encoder ROE-A Series

FEATURES

ROE-A series is an absolute encoder that uses Gray Code and reports the shaft angle within a 360oC range. As compared with other type of encoder, it can remember the position according to the mechanical position of the encoder. It means that the absolute position can be found and memorized without searching reference point. AS(Solid Shaft) AH(Hollow Shaft)

ROE-A series is an absolute encoder that uses Gray Code and reports the shaft angle within a 360oC range. As compared with other type of encoder, it can remember the position according to the mechanical position of the encoder. It means that the absolute position can be found and memorized without searching reference point. AS(Solid Shaft) AH(Hollow Shaft)

SPECIFICATIONS

AS Series: Outer Diameter of Solid Shaft: 50mm

AH Series: Outer Diameter of Hollow Shaft: 50mm

Absolute Encoder (Gray Code)

Resolution: 5-10Bit

Output Form: Voltage Output, Open Collector

Power Voltage Range: 5-12V

Responsiveness: 20kHz max

AS Series: Outer Diameter of Solid Shaft: 50mm

AH Series: Outer Diameter of Hollow Shaft: 50mm

Absolute Encoder (Gray Code)

Resolution: 5-10Bit

Output Form: Voltage Output, Open Collector

Power Voltage Range: 5-12V

Responsiveness: 20kHz max

APPLICATIONS

Label Printing Machine, Detecting Machine, Elevator, Auto Bottling Machine, Fixed Length Cutting Machine, Elevator Door.

Label Printing Machine, Detecting Machine, Elevator, Auto Bottling Machine, Fixed Length Cutting Machine, Elevator Door.

Delta ROE-C Series Rotary Optical Encoders

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta Rotary

Optical Encoder ROE-C Series

FEATURES

To meet the use requirements of encoder for CNC industry, Delta has launched a new encoder product specialized for CNC Machine Tool– CS7 series. For the solution of high resonance and much oil & gas problem occurred in machine tool application, CS7 series not only have the new mechanical design, but also provide high standard electric specifications. The corresponding rotation speed of CS7 series can achieve 8000rpm, and the response frequency of output signal can also reach 300kHZ. This new series product can satisfy the needs of all kinds of CNC machine tools

To meet the use requirements of encoder for CNC industry, Delta has launched a new encoder product specialized for CNC Machine Tool– CS7 series. For the solution of high resonance and much oil & gas problem occurred in machine tool application, CS7 series not only have the new mechanical design, but also provide high standard electric specifications. The corresponding rotation speed of CS7 series can achieve 8000rpm, and the response frequency of output signal can also reach 300kHZ. This new series product can satisfy the needs of all kinds of CNC machine tools

SPECIFICATIONS

CS Series: Outer Diameter of Solid Shaft: 70mm

Resolution: 1024ppr

Output Form: Line Driver

Power Voltage Range: 7-24V

Responsiveness: 300kHz max.

IP degree: IP55 & 70°C

CS Series: Outer Diameter of Solid Shaft: 70mm

Resolution: 1024ppr

Output Form: Line Driver

Power Voltage Range: 7-24V

Responsiveness: 300kHz max.

IP degree: IP55 & 70°C

APPLICATIONS

CNC Machine Tool

CNC Machine Tool

Delta ROE-E Series Rotary Optical Encoders

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta Rotary

Optical Encoder ROE-E Series

FEATURES

ROE-E Series is an angle-measuring sensor device which is used to detect angular velocity. It can convert the angular velocity that is input into the shaft to the corresponding pulse numbers following optical communication principle. Small size, high precision and reliable performance are its features. ROE-E Series is usually used for detecting speed, rotation direction and angular displacement.

ES(Solid Shaft)

EH(Hollow Shaft)

ET(Through Hole Shaft)

ROE-E Series is an angle-measuring sensor device which is used to detect angular velocity. It can convert the angular velocity that is input into the shaft to the corresponding pulse numbers following optical communication principle. Small size, high precision and reliable performance are its features. ROE-E Series is usually used for detecting speed, rotation direction and angular displacement.

ES(Solid Shaft)

EH(Hollow Shaft)

ET(Through Hole Shaft)

SPECIFICATIONS

ES Series: Outer Diameter of Solid Shaft: 36.6mm; Outer Diameter of Solid Shaft: 50mm EH Series: Outer Diameter of Hollow Shaft: 36.6mm; Outer Diameter of Hollow Shaft: 38.7mm; Outer Diameter of Hollow Shaft: 50mm ET Series: Outer Diameter of Through Hole Shaft: 100mm Light and compact. High reliability. Incremental Encoder. It will not increase the load of the mechanical system. Resolution: 100-5000ppr Output Form: Open Collector, Voltage Output, Line Driver, Push Pull Power Voltage Range: 5-24V Responsiveness: 300kHz max.

ES Series: Outer Diameter of Solid Shaft: 36.6mm; Outer Diameter of Solid Shaft: 50mm EH Series: Outer Diameter of Hollow Shaft: 36.6mm; Outer Diameter of Hollow Shaft: 38.7mm; Outer Diameter of Hollow Shaft: 50mm ET Series: Outer Diameter of Through Hole Shaft: 100mm Light and compact. High reliability. Incremental Encoder. It will not increase the load of the mechanical system. Resolution: 100-5000ppr Output Form: Open Collector, Voltage Output, Line Driver, Push Pull Power Voltage Range: 5-24V Responsiveness: 300kHz max.

APPLICATIONS

Label Printing Machine, Detecting Machine, Elevator, Auto Bottling Machine, Fixed Length Cutting Machine, Elevator Door

Label Printing Machine, Detecting Machine, Elevator, Auto Bottling Machine, Fixed Length Cutting Machine, Elevator Door

Delta ROE-M Series Rotary Optical Encoders

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta Rotary

Optical Encoder ROE-M Series

FEATURES

ROE-M Series is a commutation encoder which is designed for servo motor. It can not only output the signals of A,B, Z phase but also can detect the U, V, W signals of servo motor for commutation. There are 4, 6, 8, and 10 pairs of magnetic poles for user’s selection.

MH(Hollow Shaft)

MT(Through Hole Shaft)

ROE-M Series is a commutation encoder which is designed for servo motor. It can not only output the signals of A,B, Z phase but also can detect the U, V, W signals of servo motor for commutation. There are 4, 6, 8, and 10 pairs of magnetic poles for user’s selection.

MH(Hollow Shaft)

MT(Through Hole Shaft)

SPECIFICATIONS

MH Series: Outer Diameter of Hollow Shaft: 38.7mm

MT Series: Outer Diameter of Through Hole Shaft: 38.7mm

Resolution: 2500ppr

Output Form: Line Driver

Power Voltage Range: 5-12V

Responsiveness: 300kHz max

MH Series: Outer Diameter of Hollow Shaft: 38.7mm

MT Series: Outer Diameter of Through Hole Shaft: 38.7mm

Resolution: 2500ppr

Output Form: Line Driver

Power Voltage Range: 5-12V

Responsiveness: 300kHz max

APPLICATIONS

Label Printing Machine, Detecting Machine, Elevator, Auto Bottling Machine, Fixed Length Cutting Machine, Elevator Door.

Label Printing Machine, Detecting Machine, Elevator, Auto Bottling Machine, Fixed Length Cutting Machine, Elevator Door.

Delta RM-04PI Series Pulse Output Module

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives.

APPLICATIONS

Electronic components, printing machines, woodworking machines, discharge machines, adhesive machines, tube bending machines.

Electronic components, printing machines, woodworking machines, discharge machines, adhesive machines, tube bending machines.

Delta PCI-DMC-A01 Motion Control Card

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Delta Motion

Control Card PCI-DMC-A01

FEATURES

High Integrated Capability With DMCNET structure, multiple control devices such as servo motors, remote digital and analog modules, stepping motors, direct drive motors (DD motors), and linear motors can be easily and quickly connected. Up to 20Mbps communication bandwidth is provided. Maximum distance of the communication is 30m (98.4ft.) Synchronous Control Simultaneous 3-axis linear interpolation, 2-axis arc interpolation, 3-axis helical interpolation and continuous interpolation can be implemented. DMCNET is a motion control communication network which is able to update data every 1ms and offer the ability to control 12 servo system units or 4 groups, 3-axis interpolation algorithms synchronously. It is also capable of transferring the data of 12 servo motor units, or 768 digital inputs and outputs within 1ms simultaneously. Network Redundancy Function Time slot for synchronous control is provided. Master-Slave handshaking function is no more required so that the system can avoid ineffective communication and ensure the stability of data transmission when interference occurs. High-end network redundancy function is provided. There are two kinds of cyclic redundancy check (CRC) codes for two different connections. Communication errors seldom occur. Capture (Position Latch) and Compare (Position Detection) Functions With the aid of ASDA-A2 series servo system units, the Capture and Compare functions can be applied to latch and detect a reference position which could be the signal of main encoder, linear encoder, or pulse train. The DI7 is the only one high speed digital input in ASDA- A2 series servo system units. It takes only 0.5 µs to admit the signal changed. This DI is obligated to use to do Capture job.

High Integrated Capability With DMCNET structure, multiple control devices such as servo motors, remote digital and analog modules, stepping motors, direct drive motors (DD motors), and linear motors can be easily and quickly connected. Up to 20Mbps communication bandwidth is provided. Maximum distance of the communication is 30m (98.4ft.) Synchronous Control Simultaneous 3-axis linear interpolation, 2-axis arc interpolation, 3-axis helical interpolation and continuous interpolation can be implemented. DMCNET is a motion control communication network which is able to update data every 1ms and offer the ability to control 12 servo system units or 4 groups, 3-axis interpolation algorithms synchronously. It is also capable of transferring the data of 12 servo motor units, or 768 digital inputs and outputs within 1ms simultaneously. Network Redundancy Function Time slot for synchronous control is provided. Master-Slave handshaking function is no more required so that the system can avoid ineffective communication and ensure the stability of data transmission when interference occurs. High-end network redundancy function is provided. There are two kinds of cyclic redundancy check (CRC) codes for two different connections. Communication errors seldom occur. Capture (Position Latch) and Compare (Position Detection) Functions With the aid of ASDA-A2 series servo system units, the Capture and Compare functions can be applied to latch and detect a reference position which could be the signal of main encoder, linear encoder, or pulse train. The DI7 is the only one high speed digital input in ASDA- A2 series servo system units. It takes only 0.5 µs to admit the signal changed. This DI is obligated to use to do Capture job.

SPECIFICATIONS

Supports Delta ASDA-A2-F series AC servo drives

35 kinds of homing modes

T-curve / S-curve velocity profiles

Linear, circular and continuous interpolation supported

Supports VB, VC, BCB, DELPHI, C#, VB.NET tool languages

PCI Specifications Ver.2.2, supports 32-bit, 3.2V/5VDC operation Complies with noise ordinances Operating Temperature: 0oC~50oC; Storage Temperature: -20oC~70oC; Humidity: 5~95% (non-condensing)

Supports Delta ASDA-A2-F series AC servo drives

35 kinds of homing modes

T-curve / S-curve velocity profiles

Linear, circular and continuous interpolation supported

Supports VB, VC, BCB, DELPHI, C#, VB.NET tool languages

PCI Specifications Ver.2.2, supports 32-bit, 3.2V/5VDC operation Complies with noise ordinances Operating Temperature: 0oC~50oC; Storage Temperature: -20oC~70oC; Humidity: 5~95% (non-condensing)

APPLICATIONS

Electronic components, printing machines, woodworking machines, discharge machines, adhesive machines, tube bending machines

Electronic components, printing machines, woodworking machines, discharge machines, adhesive machines, tube bending machines

Delta RM Series Remote Extension Modules

|

We provide all Delta AC Drives, VFD’s,

Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion

Control Network, Delta Programmable Logic Controller, Delta Human

Machine Interfaces, Delta Text Panels, Delta Temperature Controllers,

Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta

Brushless DC Motors as well as Delta Brushless DC Drives. Remote

Extension Modules – RM Series

FEATURES

High-speed remote extension modules are designed for real-time data acquisition for establishing a cost-effective remote I/O system which substantially increases the purchase of Delta High-Speed Motion Control System, DCMNET.

High-speed remote extension modules are designed for real-time data acquisition for establishing a cost-effective remote I/O system which substantially increases the purchase of Delta High-Speed Motion Control System, DCMNET.

SPECIFICATIONS

General Specifications

Power Supply Voltage: 24VDC (15% ~ 20%)

ESD: 8KV Air Discharge

EFT: Power Line-2KV

Digital I/O 1KV

RS: 80MHz ~ 1GHz, 10V/m

Operating Temperature: 0°C ~ 50°C

Electrical Specifications of Digital Input Modules

Circuit Type: Single

Signal Type: SINK / SOURCE

Power Supply Voltage: 24VDC(5mA)

Response Time: 0 ~ 3ms (adjustable)

Active Level (OFF->ON): >16.5VDC

Active Level (ON->OFF): <8VDC

Electrical Specifications of Digital Output Modules

Circuit Type: Transistor

Signal Type: SINK

Work Frequency: 10KHz

Current Specifications: 0.1A/1point @40°C

Voltage Specifications: 24VDC

Active Level (OFF->ON):20us

Active Level (ON->OFF):30us

General Specifications

Power Supply Voltage: 24VDC (15% ~ 20%)

ESD: 8KV Air Discharge

EFT: Power Line-2KV

Digital I/O 1KV

RS: 80MHz ~ 1GHz, 10V/m

Operating Temperature: 0°C ~ 50°C

Electrical Specifications of Digital Input Modules

Circuit Type: Single

Signal Type: SINK / SOURCE

Power Supply Voltage: 24VDC(5mA)

Response Time: 0 ~ 3ms (adjustable)

Active Level (OFF->ON): >16.5VDC

Active Level (ON->OFF): <8VDC

Electrical Specifications of Digital Output Modules

Circuit Type: Transistor

Signal Type: SINK

Work Frequency: 10KHz

Current Specifications: 0.1A/1point @40°C

Voltage Specifications: 24VDC

Active Level (OFF->ON):20us

Active Level (ON->OFF):30us

APPLICATIONS

ectronic components, printing machines, woodworking machines, discharge machines, adhesive machines, tube bending machines

ectronic components, printing machines, woodworking machines, discharge machines, adhesive machines, tube bending machines

Delta DVP-10PM Series

|

This series highlights high-speed command

execution speed (basic command LD for 0.1375µs, application command

MOV for 2.1µs and 1MHz differential output*4) to achieve precise

motion control. Delta Professional Motion Control MPU Series &

DVP-10 PM Series We provide all Delta AC Drives, VFD’s, Delta AC

Servo Motors, Delta Rotary Optical Encoders, Delta Motion Control

Network, Delta Programmable Logic Controller, Delta Human Machine

Interfaces, Delta Text Panels, Delta Temperature Controllers, Delta

Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta Brushless DC

Motors as well as Delta Brushless DC Drives.

SPECIFICATIONS

DVP-10PM Series

MPU points: 24

Max. I/O points: 256

Program capacity: 64k steps

Built-in hardware digital filter for counting

6 high-speed counters (O.C. 200kHz*4, differential 200kHz*2), supporting U/D, U/D Dir, A/B, 4A/B counting modes

4 differential 1MHz outputs, supporting U/D, U/D Dir, A/B output modes Supports 1-speed (immediate stop after the mark arrives), 2-speed, zero return, MPG and single axis function Highly accurate PWM 200kHz output, resolution 0.3% Electronic gear function

8 high-speed captures (mark correction, frequency measurement), comparative output, mark/mask function (for bag making)

8 external interruptions for setting up rising – and falling-edge triggers, 1 timed interruption Highly efficient command execution. LD: 0.1375µs, MOV: 2.1µs

DVP-10PM Series

MPU points: 24

Max. I/O points: 256

Program capacity: 64k steps

Built-in hardware digital filter for counting

6 high-speed counters (O.C. 200kHz*4, differential 200kHz*2), supporting U/D, U/D Dir, A/B, 4A/B counting modes

4 differential 1MHz outputs, supporting U/D, U/D Dir, A/B output modes Supports 1-speed (immediate stop after the mark arrives), 2-speed, zero return, MPG and single axis function Highly accurate PWM 200kHz output, resolution 0.3% Electronic gear function

8 high-speed captures (mark correction, frequency measurement), comparative output, mark/mask function (for bag making)

8 external interruptions for setting up rising – and falling-edge triggers, 1 timed interruption Highly efficient command execution. LD: 0.1375µs, MOV: 2.1µs

APPLICATIONS

Used for 2-axis servo positioning control, material cutting machine (high-speed servo control), crane operations, material clipper controlled by the servo.

Used for 2-axis servo positioning control, material cutting machine (high-speed servo control), crane operations, material clipper controlled by the servo.