- DELTA PRODUCTS

- - Delta Products1

- - Delta Products2

- - Delta Products3

- - Delta Products4

- - Delta Products5

- OMRON PRODUCT

- - Omron Products

- ELECTRIC DRIVE

- - Low Voltage Inverter

- - High Voltage Inverter

- - Intelligent Integral Machine

- INDUSTRIAL CONTROL

- - Servo System

- - PLC

- - HMI

- A/C Drives

- - Architecture Drives

- - Compact Drives

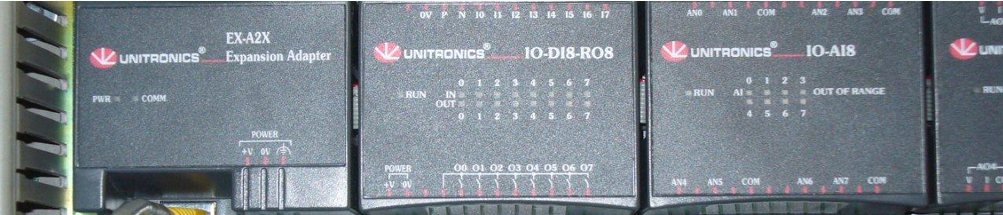

- Programmable Controllers

- - Large Control Systems

- - Micro & Nano Control Systems

- - Small Control Systems

- HMI Human Machine Interface

- - Computers, Extreme Environment

- - Computers, Industrial Environment

- - Graphic Terminals

- - Industrial Monitors

Home »

Our Products » Omron Products

Omron Products

Machine Interface NA Series

|

An HMI that is dynamic, intuitive and predictive

makes industrial machines more attractive and competitive. The Omron HMI

enables faster, more efficient control and monitoring - and a more

natural, proactive relationship between operator and machine. The design

has been based on real applications and customer requirements, a

future-proofed, scalable platform that will evolve with their

ever-changing needs, allowing real time reaction to events. As part of

the system family, the NA Series is fully aware of the total machine.

- Proactive operator/ machine relationship

- Design based on real applications and customer requirements

- Future-proof, scalable platform

- Allows quick reaction

Nb Series Data Sheet

|

The feature-rich, economic HMI

- More than 65,000 display colours TFT touch screen

- Available in sizes ranging from 3.5 to 10 inches

- Long-life LED backlight

- Serial, USB or Ethernet communication

- USB memory stick support

- 128 MB internal memory

- Vector and bitmap graphics

PLC CP1E

|

Responding to Global Competition with More

Device Control Possibilities

The CP1E all-in-one package PLCs provide high cost performance to further reduce costs by allowing you to select the optimal CPU Unit from the E-type Basic Models or N/NA-type Application Models.

The CP1E all-in-one package PLCs provide high cost performance to further reduce costs by allowing you to select the optimal CPU Unit from the E-type Basic Models or N/NA-type Application Models.

Instruction and Address Input Assist

Functions

When you begin typing an instruction from the keyboard while in the Ladder Editor Window, suggested instructions are displayed. All you have to do is select the instruction from the list for easy input even if you do not remember the entire mnemonic.

When you begin typing an instruction from the keyboard while in the Ladder Editor Window, suggested instructions are displayed. All you have to do is select the instruction from the list for easy input even if you do not remember the entire mnemonic.

Address Incrementing

The address of the next operand, including input bits and output bits, is incremented by one and displayed as the default. This enables easily inputting consecutive addresses.

The address of the next operand, including input bits and output bits, is incremented by one and displayed as the default. This enables easily inputting consecutive addresses.

Sysmac CJ1

|

Pulse Outputs

- From stepping motors to servos, positioning control can be easily achieved using pulse outputs for one or two axes.

- Pulse output control is enabled from 1 Hz to 100 kHz.

- Startup times as fast as 46 µs reduce tact times and enable high-precision positioning.

- A high-precision variable duty ratio (PWM) can be output in 0.1% increments and used in applications such as lighting and electric power control.

- Using special instructions and OMRON Function Blocks for positioning makes programming easy even for first-time users.

Origin Search

- An origin search or return operation can be executed with a single command.

- A wide range of origin search patterns is available, so the optimum origin search pattern can be selected for the machine design.

- When a Servomotor is used, position deviation is minimized by a deviation counter reset output.

Positioning

Speed control or positioning using relative or absolute coordinates can be executed with a single command. A wide range of functions is available for positioning to suit your application.

Speed control or positioning using relative or absolute coordinates can be executed with a single command. A wide range of functions is available for positioning to suit your application.

CJ1 Special I/O Units Process Analog Input Units

|

Function blocks make loop-control programming

easy. You can also create CX-Process Tool tuning windows to help adjust

loops. Controller faceplates can be created automatically for touch

panel displays.

Sequence control programs: Standardize and simplify programs using structured programming. Special I/O Unit and CPU Bus Unit settings are easy with function blocks (using ladder programming language or structured text). Loop control programs: By combining function blocks, a wide array of control methods can be easily configured, from basic PID control used by Temperature Controllers to program, cascade, and feed-forward control. Easily display values, such as temperatures, in engineering units, allowing you to check operation.

Simply turn the DIP Switch ON/OFF to save or read the user program including function blocks using the Memory Card.

Simple backup function enables backup, recovery, and comparison of all PLC data including the function block programs for the Loop Control Board using the Memory Card. Save tag settings, comments, annotations, and connection data created using the CX-Process Tool to either a Memory Card or a Loop-control CPU Unit.

Sequence control programs: Standardize and simplify programs using structured programming. Special I/O Unit and CPU Bus Unit settings are easy with function blocks (using ladder programming language or structured text). Loop control programs: By combining function blocks, a wide array of control methods can be easily configured, from basic PID control used by Temperature Controllers to program, cascade, and feed-forward control. Easily display values, such as temperatures, in engineering units, allowing you to check operation.

Simply turn the DIP Switch ON/OFF to save or read the user program including function blocks using the Memory Card.

Simple backup function enables backup, recovery, and comparison of all PLC data including the function block programs for the Loop Control Board using the Memory Card. Save tag settings, comments, annotations, and connection data created using the CX-Process Tool to either a Memory Card or a Loop-control CPU Unit.

CJ-Series Process Analog I/O Unit

|

A Single Unit Handling All Types of Inputs such

as Temperature Sensor Inputs and Analog Signal Inputs (e.g., 4 to 20 mA

or 1 to 5 V)

A Unit supports four input channels, each of which can be set to a platinum resistance thermometer, thermocouple, and DC signal (current, voltage). All inputs are isolated.

A Unit supports four input channels, each of which can be set to a platinum resistance thermometer, thermocouple, and DC signal (current, voltage). All inputs are isolated.

FEATURES

- Supports a maximum of four inputs in one Unit: resistance thermometer, thermocouple, and DC current/voltage. (The input type is set separately for each input.)

- Isolation between input channels prevents unwanted current paths between input channels.

- Scaled values are transferred to the CPU Unit in four digits hexadecimal with voltage/current inputs.

- Process value alarm with two alarms for each input

- Alarm ON-delay timer and hysteresis for process value

- Zero/Span adjustment capability during operation

- Input error detection

- Maximum or minimum process value can be specified for when an input error is detected.

- A Unit with fully universal inputs, high-speed and high-resolution (256,000 resolution, 60 ms/ch is available.)

CJ2 Family

|

Omron has used its long experience as a

specialist machine automation supplier to develop CJ2. The result is an

extremely reliable PLC that is also a powerful example of our commitment

to continuous improvement. The CJ2 Family is a major opportunity to

innovate and simultaneously reduce cost now and in the future. It’s

the obvious choice for modern machine builders.

Wide range CPU capacity

To stay ahead in the machine-building business, you need to grow with your end-user’s needs. Faster production, better quality control and better traceability require more speed and more memory. That’s why the CJ2 Family offers a wide range of CPUsto suit any task. From 5 Ksteps program capacity and 64 Kwords memory, right up to 500 Ksteps capacity and 832 Kwords.

Higher precision

In addition to the greater CPU processing performance, Omron has also added new high-speed I/O units, such as analog input units with 20 µs conversion time, while new PLC instructions provide immediate access to fast I/O data. The result is even more real-time reliability.

Select what you need

With CJ2 you can also still connect to the existing CJ1 I/O units. You can benefit from CJ2’s improvements without redesigning the entire system.

Wide range CPU capacity

To stay ahead in the machine-building business, you need to grow with your end-user’s needs. Faster production, better quality control and better traceability require more speed and more memory. That’s why the CJ2 Family offers a wide range of CPUsto suit any task. From 5 Ksteps program capacity and 64 Kwords memory, right up to 500 Ksteps capacity and 832 Kwords.

Higher precision

In addition to the greater CPU processing performance, Omron has also added new high-speed I/O units, such as analog input units with 20 µs conversion time, while new PLC instructions provide immediate access to fast I/O data. The result is even more real-time reliability.

Select what you need

With CJ2 you can also still connect to the existing CJ1 I/O units. You can benefit from CJ2’s improvements without redesigning the entire system.

SYSMAC CJ-series CJ2M CPU Units

|

- Increased performance, and increased memory capacity

- Up to 40 I/O units on any CPU

- USB for plug-and-play access to the PLC

- All models available with or without Ethernet port

- Choice of serial port plug-in modules

- User-friendly programming, faster debugging

FEATURES

- Five variations in program capacity from 5K steps to 60K steps; scale the CPU to your application needs.

- Faster processors; LD instruction execution time is reduced to 40 ns, floating point trigonometrics in less than 1 µs..

- Faster Function Block calls and execution, faster interrupt handling, less overhead time.

- Added execution memory for Function Blocks allows structured, object-oriented programming even in entry-level CPUs.

- General-purpose Ethernet port supports EtherNet/IP tag-based data links, connection to Support Software, communications between PLCs,

- FTP data transfers, and more (CJ2M-CPU3@).

- Standard USB port on all models allows Support Software to connect directly through standard USB cable.

- A Serial Option Module can be mounted to add RS-232C or RS-422A/485 communications ports (CJ2M-CPU3@).

- Compatible with all existing CJ1 power supply-, I/O-, control- and communication units.

CP1 Family

|

Fast and versatile communication

Flexible, fast and yet cost-effective communication is essential in today’s competitive market. This applies in particular to compact Programmable controllers, which not only need to connect with devices inside the machine, but also outside the machine for operating, data-logging and remote access. With this in mind, Omron has given the CP1 family excellent communication capabilities for both serial and Ethernet networking. In addition, Omron provides flexible and economical option boards for serial communication.

Flexible, fast and yet cost-effective communication is essential in today’s competitive market. This applies in particular to compact Programmable controllers, which not only need to connect with devices inside the machine, but also outside the machine for operating, data-logging and remote access. With this in mind, Omron has given the CP1 family excellent communication capabilities for both serial and Ethernet networking. In addition, Omron provides flexible and economical option boards for serial communication.

Easy positioning functions

The CP1 family is designed to fulfill position control tasks. Up to four axes of servo-drives can be controlled with high-speed pulse outputs, while high-speed pulse inputs can allow the connection of up to four encoders. Control is easily achieved with Function Block or standard functions without the need of specialist motion boards or expansion units. Furthermore, thanks to its fast serial ports, the CP1 family is also capable of performing simple positioning tasks. With the use of Modbus Function Blocks, up to 31 inverters can be controlled and monitored in real-time.

The CP1 family is designed to fulfill position control tasks. Up to four axes of servo-drives can be controlled with high-speed pulse outputs, while high-speed pulse inputs can allow the connection of up to four encoders. Control is easily achieved with Function Block or standard functions without the need of specialist motion boards or expansion units. Furthermore, thanks to its fast serial ports, the CP1 family is also capable of performing simple positioning tasks. With the use of Modbus Function Blocks, up to 31 inverters can be controlled and monitored in real-time.

Flexible Ethernet connectivity

To meet communication needs over different protocols simultaneously and to easily connect for remote access, our latest CP1L Programmable controller features embedded Ethernet with socket services functionality. This offers, among other things, programmable connectivity to third-party devices and makes this outstanding product the best-in-class machine controller on the market.

To meet communication needs over different protocols simultaneously and to easily connect for remote access, our latest CP1L Programmable controller features embedded Ethernet with socket services functionality. This offers, among other things, programmable connectivity to third-party devices and makes this outstanding product the best-in-class machine controller on the market.

Ideal for position control

When simplicity and ease of use are essential, there is no better solution for your position applications than combining the CP1 family with servos and inverters from Omron’s extensive range. The SmartStep 2 servo drive is a perfect partner and offers high performance while keeping things simple and cost effective. Omron provides standard functions and Function Blocks for SmartStep 2 and other servo drives to create your application with minimal effort.

When simplicity and ease of use are essential, there is no better solution for your position applications than combining the CP1 family with servos and inverters from Omron’s extensive range. The SmartStep 2 servo drive is a perfect partner and offers high performance while keeping things simple and cost effective. Omron provides standard functions and Function Blocks for SmartStep 2 and other servo drives to create your application with minimal effort.

Easy variable speed drive control

Variable speed drive control is made easy within the CP1 family by using the serial port(s) and the Easy Modbus Master feature for high-speed communication. Omron Function Blocks enable you to control and monitor up to 31 inverters in realtime simply by configuration of parameters. With the encoders connected to the high-speed counter inputs, the CP1 is able to calculate the exact position to perform accurate positioning easily and quickly. In addition, in the MX2 inverter series, all simple positioning is handled within the drive itself.

Variable speed drive control is made easy within the CP1 family by using the serial port(s) and the Easy Modbus Master feature for high-speed communication. Omron Function Blocks enable you to control and monitor up to 31 inverters in realtime simply by configuration of parameters. With the encoders connected to the high-speed counter inputs, the CP1 is able to calculate the exact position to perform accurate positioning easily and quickly. In addition, in the MX2 inverter series, all simple positioning is handled within the drive itself.

Sysmac CP1E

|

Responding to Global Competition with More

Device Control Possibilities

The CP1E all-in-one package PLCs provide high cost performance to further reduce costs by allowing you to select the optimal CPU Unit from the E-type Basic Models or N-type Application Models.

The CP1E all-in-one package PLCs provide high cost performance to further reduce costs by allowing you to select the optimal CPU Unit from the E-type Basic Models or N-type Application Models.

Easy Input Editor

Instruction and Address Input Assist

Functions

When you begin typing an instruction from the keyboard in Ladder Editor Mode, suggested instructions are displayed and the addresses are automatically entered. Connecting lines are added automatically based on the cursor position, enabling intuitive ladder programming.

When you begin typing an instruction from the keyboard in Ladder Editor Mode, suggested instructions are displayed and the addresses are automatically entered. Connecting lines are added automatically based on the cursor position, enabling intuitive ladder programming.

Easily Reuse Ladder Programming

Copying with Address Incrementing

To create the same group of ladder instructions more than once, with the address addition copy function, the instructions can be reused simply by inputting an address offset.

To create the same group of ladder instructions more than once, with the address addition copy function, the instructions can be reused simply by inputting an address offset.

Intuitive Menu Structure

Intuitive Menu Display

An intuitively designed menu structure makes it easy to see the overall system simply by looking at the menu for smooth operation without referring to a manual.

An intuitively designed menu structure makes it easy to see the overall system simply by looking at the menu for smooth operation without referring to a manual.

CP1E

|

Responding to Global Competition with More

Device Control Possibilities

The CP1E provide high cost performance to further reduce costs by allowing you to select the optimal CPU Unit from the ES-type Basic Models or N/S(1)-type Application Models.

When you begin typing an instruction from the keyboard while in the Ladder Editor Window, suggested instructions are displayed. All you have to do is select the instruction from the list for easy input even if you do not remember the entire mnemonic.

The address of the next operand, including input bits and output bits, is incremented by one and displayed as the default. This enables easily inputting consecutive addresses.

The CP1E provide high cost performance to further reduce costs by allowing you to select the optimal CPU Unit from the ES-type Basic Models or N/S(1)-type Application Models.

When you begin typing an instruction from the keyboard while in the Ladder Editor Window, suggested instructions are displayed. All you have to do is select the instruction from the list for easy input even if you do not remember the entire mnemonic.

The address of the next operand, including input bits and output bits, is incremented by one and displayed as the default. This enables easily inputting consecutive addresses.

CP series CP1L CPU Unit

|

High Performing Programmable Controller with

Embedded Ethernet

- "CP1L-EM" and "CP1L-EL" has a standard-feature Ethernet port.

- "CP1L-M" and "CP1L-L" has a standard-feature peripheral USB port.

- Function blocks (FB) allow you to build up modular structure and programming of ladder diagrams.

FEATURES

- "CP1L-EM" and "CP1L-EL" have complete with a Ethernet port.

- Pulse output for two axes. Advanced power for high-precision positioning control.

- High-speed Counters. Single-phase for four axes.

- Six interrupt inputs are built in. Faster processing of instructions speeds up the entire system.

- Serial Communications. Two ports. Select Option Boards for either RS-232C or RS-485 communications.

- "CP1L-M" and "CP1L-L" have a peripheral USB port.

- The Structured Text (ST) Language. Makes math operations even easier.

- Can be used for the CP1W series Unit. The extendibility of it is preeminently good.

- LCD displays and settings. Enabled using Option Board.

CS1D Duplex System

|

In addition to duplexed CPU Units and Power

Supply Units, the customer can duplex other components, such as

Communications Units (Controller Link or Ethernet) and Expansion Cables,

to match the system requirements and provide a diverse range of duplex

system configurations.

Ethernet can be duplexed as well as Controller

Link, which both have a proven track record in FA applications. In

addition, a variety of networks are available for lower-level I/O,

including Device Net, Compo Net, and the MECHATROLINK-II Motion

Controller network. Both DeviceNet and CompoNet are open networks that

boast a proven track record with the CS1 Series.

FA Controller

|

Omron has developed automation technology

through the development of sensors, switches, PLC, programmable

terminals, servo drives, inverters and other products. Now devices

connected via standard networks change into new solutions for various

machine environments.

The cost-effective CP Series and complete,

robust Sysmac NJ/NX Series support from simple machine control through

to large production line control and plant management.

The controllers not only help reduce

programming, set-up and maintenance times, but also enable fast and

accurate fine-tuning control, quality traceability, predictive

maintenance, preventive maintenance, and remote maintenance.

J7 Users

|

General Precautions

- Some drawings in this manual are shown with the protective cover or shields removed, in order to describe detail with more clarity. Make sure all covers and shields are replaced before operating this product.

- This manual may be modified when necessary because of improvement of the product, modification, or changes in specifications. Such modifications are denoted by a revised manual No.

- To order a copy of this manual, if your copy has been damaged or lost, contact your OYMC representative.

- OYMC is not responsible for any modification of the product made by the user, since that will void your guarantee.

M2JC

|

- Increased performance, and increased memory capacity

- Up to 40 I/O unit on any CPU

- Pulse I/O Modules add position control functions to any CPU

- USB for plug-and-play access to the PLC

- All models available with or without Ethernet port

- Choice of serial port plug-in modules

FEATURES

- Five variations in program capacity from 5K steps to 60K steps; scale the CPU to your application needs.

- Faster processors; LD instruction execution time is reduced to 40 ns, floating point trigonometrics in less than 1 µs.

- Optional Pulse I/O Modules can be mounted to enable positioning functions for up to four axes. The module provides high-speed counters, interrupt inputs and pulse train/PWM outputs. (CJ2M CPU Units with Unit Version 2.0 or Later)

- Faster Function Block calls and execution, faster interrupt handling, less overhead time.

- Added execution memory for Function Blocks allows structured, object-oriented programming even in entry-level CPUs.

- General-purpose Ethernet port supports EtherNet/IP tag-based data links, connection to Support Software, communications between PLCs, FTP data transfers, and more (CJ2M-CPU3@).

- Standard USB port on all models allows Support Software to connect directly through standard USB cable.

- A Serial Option Module can be mounted to add RS-232C or RS-422A/485 communications ports (CJ2M-CPU3@).

- Compatible with all existing CJ1 power supply-, I/O-, control- and communication units.

NJ/NX Controller

|

One machine control through one connection and one software is how we define the Sysmac automation platform. The Machine Automation Controller integrates logic, motion, safety, robotics, vision, information, visualization and networking under one software: Sysmac Studio. This one software provides a true Integrated machine controller comes standard with built-in EtherCAT EtherNet/IP. The two with one connection purpose is the perfectmatch between fast real time machine control and data plant management.

NSJ Series

|

As production becomes increasingly globalized, the needs for standardized control panels are growing. With its new, one-package concept, the SYSMAC One NSJ Series contributes to reducing both hardware and software requirements for control panels. While offering the same convenient operation for control panels in any factory, any process, and any device worldwide, the NSJ Series eliminates various forms of inefficiency, waste, and inconsistency that extend all the way from device design and installation, to maintenance.